V Belt

Product Details:

V Belt Price And Quantity

- 300 INR/Piece

- 20 Piece

V Belt Trade Information

- Telegraphic Transfer (T/T) Cash in Advance (CID) Cash Advance (CA)

- 1000 Piece Per Month

- 4 Week

- All India

Product Description

Key Features:

- Simple to remove and install with a rugged design, smooth finish, and longer life

- An adjusted combination and premium bonding of components

- Increased productivity, high temperature, shock load and hefty bending fatigue

- Can effectively enhance the productivity

- Assure elevated load capacity, longer functional life, and least maintenance

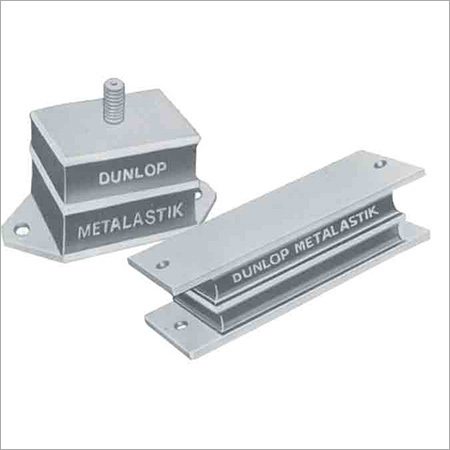

Industrial Vee Belts

The exclusive design of the load-carrying polyester cords-involving a balanced twist, supplemented by a special treatment-give the balanced combination of strength, modulus, energy of rupture, adhesion, thermal and fatigue life, properties demanded by a wide range of applications.

Perfect Hi-Polymer

Compound-impregnated jacket

- The jacket is an unbeatable combination perfected by Dunlop for optimum performance in all conditions.

- The jacket fabric, woven to close specifications, assures adequate adhesion to the rubber compound with which it is processed.

- Result-abrasion-resistance that excels in dusty, girtty conditions.

The unique Hi-polymer compound provides.

- Superior oil resistance

- Excellent heat resistance

- Improved wear resistance

- Electrical properties

Specialised Rubber compounds:

Backed by the Mitsuboshi experience, the base and cushion compounds are designed after extensive study of the failure patterns of vee belts prevalent in industry. The compounds are mixed to close specifications in microprocessor-controlled internal mixers for a precisely controlled cycle. Continuous quality control is applied to ensure that all the batches are with in set specification limits. The cushion compound retains the dynamic bond under all adverse ambient conditions.

The base rubber not only provides an engineered anisotropy to meet product design parameters, it is a cooler running compound as well, designed to avoid crack growth

VEE Belt Tensioning:

Proper tensioning is a fundamental factor in the successful vee belt operation. Lack of tension will cause slippage and too much tension will cause excessive belt stretch as well as damage to the drive components such as bearing and shafts. Therefore to assure proper belt tension, following procedure is recommended.

- Measure the length of span in millimeters

- At the centre of the span apply a force with spring scale in a direction perpendicular to the span, until the belt is deflected from the normal by an amount equal to 0.015 mm for every millimeter of span length.

- Not the force and compare it with value given in table below.

Tensioning forces

|

Belt cross section |

Smaller pulley diameter (mm) |

Force required to deflect belt 0.015 mm per millimeter of span |

|

|

Kilogram force (kgf) |

Newton (N) |

||

|

A |

80 to 140 |

1.0 to 1.5 |

10 to 15 |

|

B |

125 to 200 |

2.0 to 3.1 |

20 to 30 |

|

C |

200 to 400 |

4.1 to 6.1 |

40 to 60 |

|

D |

350 to 600 |

7.7 to 11.2 |

75 to 110 |

|

E |

500 and above |

9.6 to 14.3 |

95 to 140 |

If the measured force is below the lower value, it indicates undertensioning, whilst a measured force above the higher value indicates overtensioning. However, when starting up a drive with new belts, the drive should be tensioned to the higher value since the tension falls rapidly in the early stages of running in.

Dunlop Dynamitz polyester cord vee belts are available in A,B,C,D,&E sections up to Size 418

|

Nominal Dimension |

Length range |

||||

|

Section |

Top width (mm) |

height (mm) |

Angle (degree) |

Inside length (inch) |

Pitch length (mm) |

|

A |

13 |

8 |

40 |

23 to 174 |

620 to 4456 |

|

B |

17 |

11 |

40 |

26 to 278 |

703 to 7104 |

|

C |

22 |

14 |

40 |

46 to 360 |

1224 to 9200 |

|

D |

32 |

19 |

40 |

109 to 418 |

2848 to 10696 |

|

E |

38 |

23 |

40 |

180 to 418 |

4664 to 10709 |

| SPZ |

10 |

6 |

40 |

- |

- |

| SPA |

13 |

9 |

40 |

- |

- |

| SPB |

17 |

13 |

40 |

- |

- |

| SPC |

22 |

18 |

40 |

- |

- |

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

|

DUNLOP INDUSTRIAL PRODUCTS PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |